888-PB

888_ECO_CLASSIC_208 mm_302 mm_436,5 mm

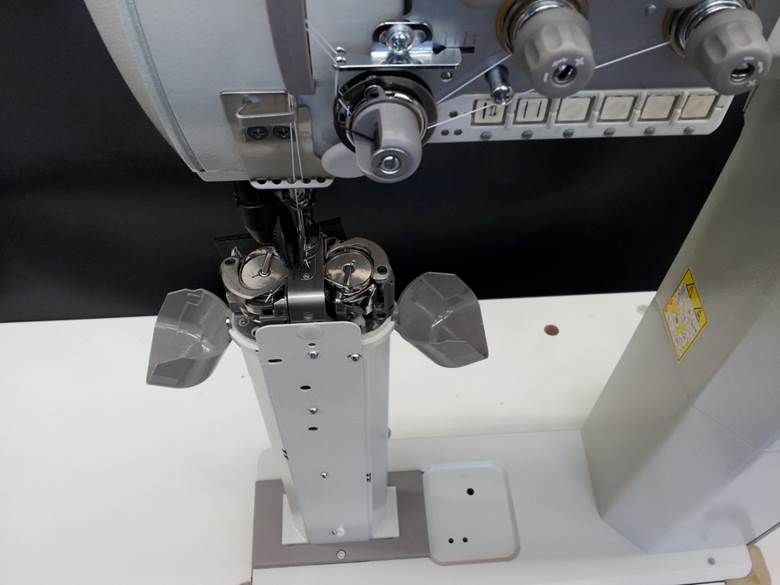

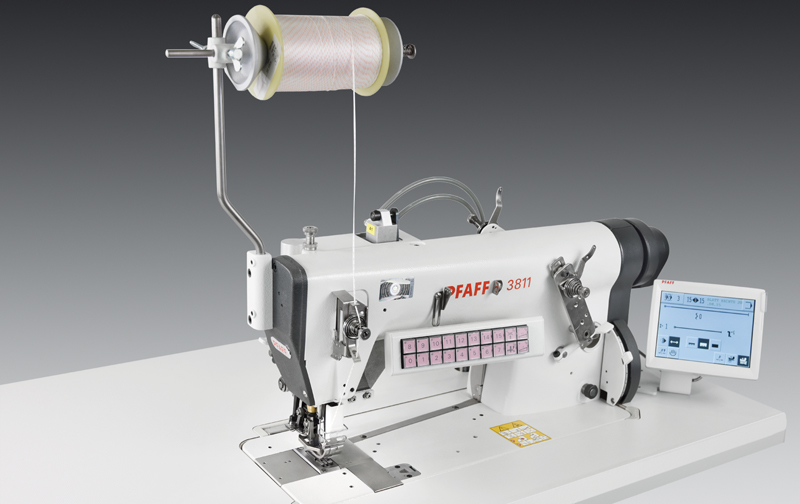

Post bed lockstitch machines

888-PB

Our standard zigzag machines are available in different lengths for light / medium weight applications. This ensures adaptation of our proven sewing technology for applications on large-sized workpieces.

888-PB

52Xi_188 mm_294 mm Post bed zig zag machines

General advantages:

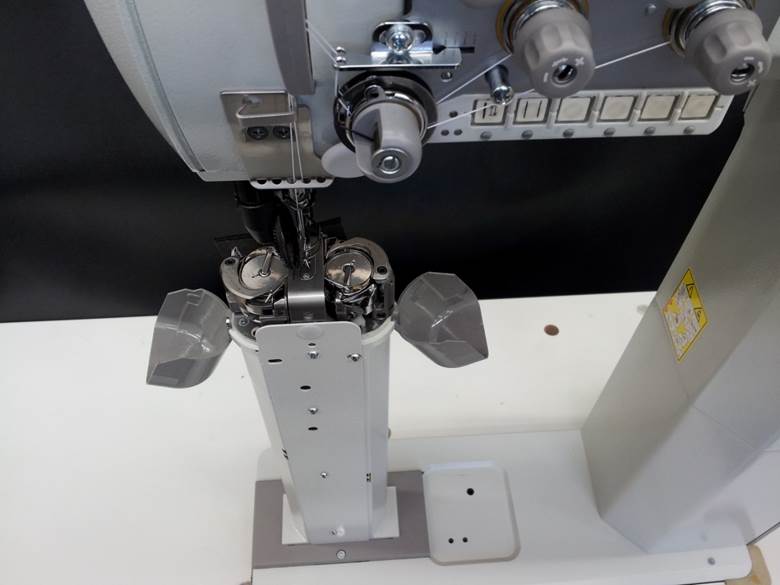

- Thread trimmer (CLASSIC) ensures secured cutting, also for thick threads up to 20/3

- Modified lubrication and a reservoir in the machine arm reduce maintenance, guarantee the correct lubrication doses and protect the hook against wear.

- Optimized thread trimming system with adjustable bobbin break spring (CLASSIC version) for better stitching results

- Needle thread tension regulation for more precise tension adjustment

- Ergonomic bobbin winder with easier adjustment of max. value

- Improved working conditions for the operator by reduced noise level and less vibrations

- Modern zigzag setting device – easy adjustment of zigzag width with low force

- Easy stitch length setting – adjustment without lever by turn button

- Back tacking and needle position up/down via push buttons (CLASSIC)

- Use of incorporated mini motor and quick connection from the head to the motor (CLASSIC)

- Integrated LED sewing light (optional)

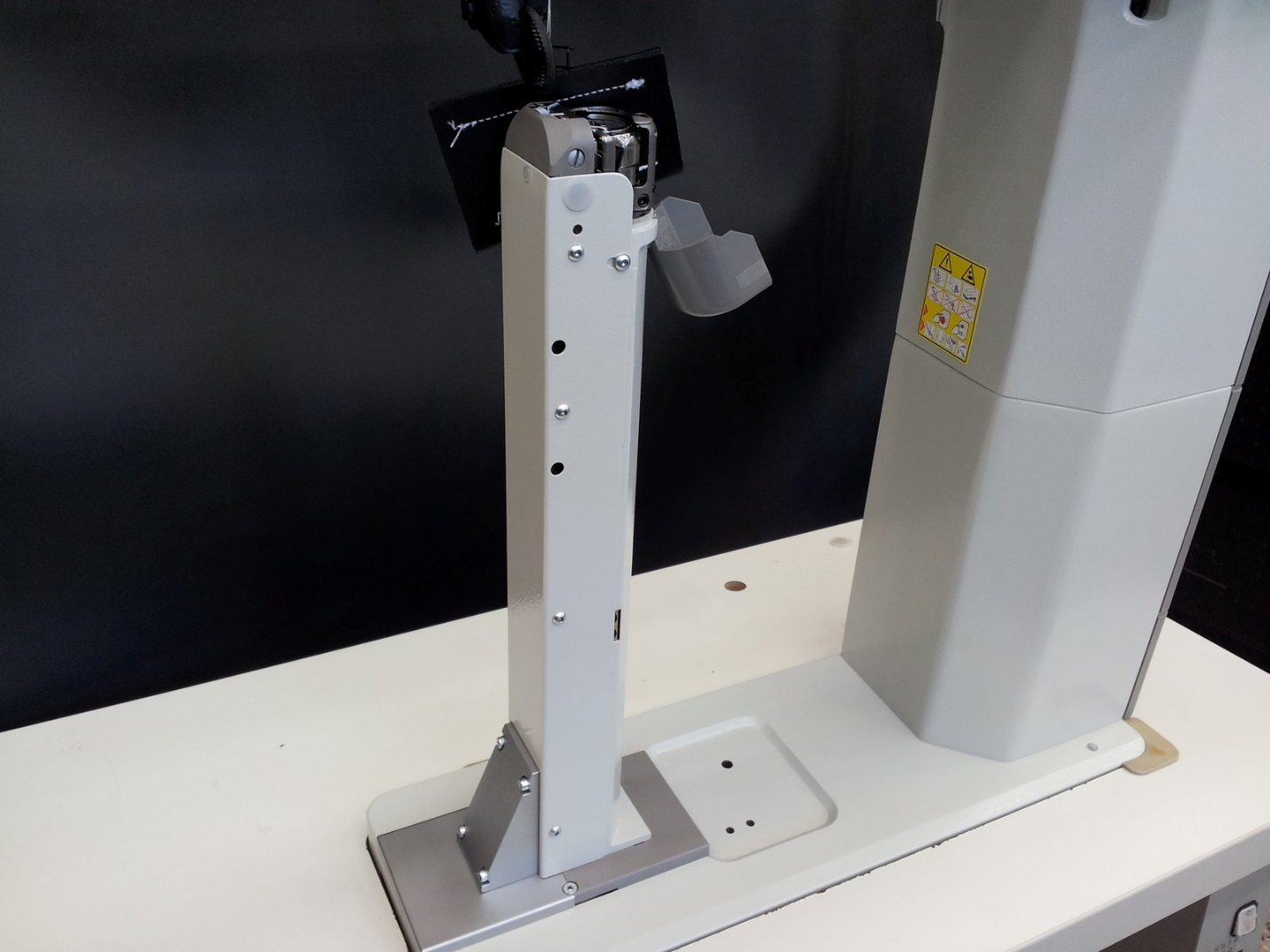

- Long arm zig zag machines

- Various arm lengths available

- Machines can be equipped with mechanically, or pneumatically driven puller (optional)

- Backtacking and foot lifting, pneumatically driven (optional)

- Needle cooling device (optional)

- Arm clearance can be increased to 183 mm (optional)

- Extra heavy stand + table top available (optional)

- All types of Dürkopp Adler zigzag sewing machines are available as long arm machines

- These machines are used for manufacturing and repairing large dimensioned workpieces, such as windsurfing sails, wetsuits, tents, awnings etc.

- An intermittent puller, as optional equipment, allows a high performance. The feeding assistance from above avoids material shifting. Puller is available with different widths of feeding wheel.

- Easy operating of backtacking and puller lifting by means of ergonomically designed push buttons.

- Sewing equipment for binding operations.