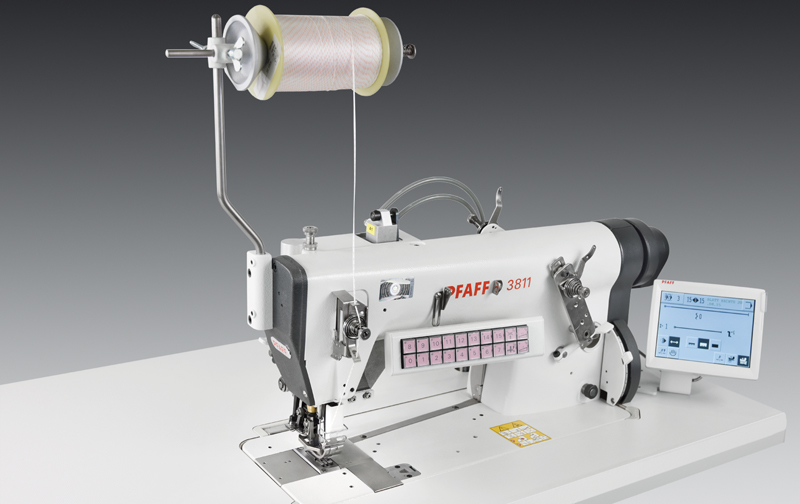

887-363522-M

Single needle lockstitch flat bed machine with DA Direct Drive, pneumatic activated edge trimmer driven by electric motor, wheel feed, needle feed and top driven roller, with electromagnetic thread trimmer, electropneumatic auto back-tacking and auto presser-foot lift.

887-M

CLASSIC

Single needle flat bed sewing machine with vertical edge trimmer with integrated DA Direct Drive

Your advantages

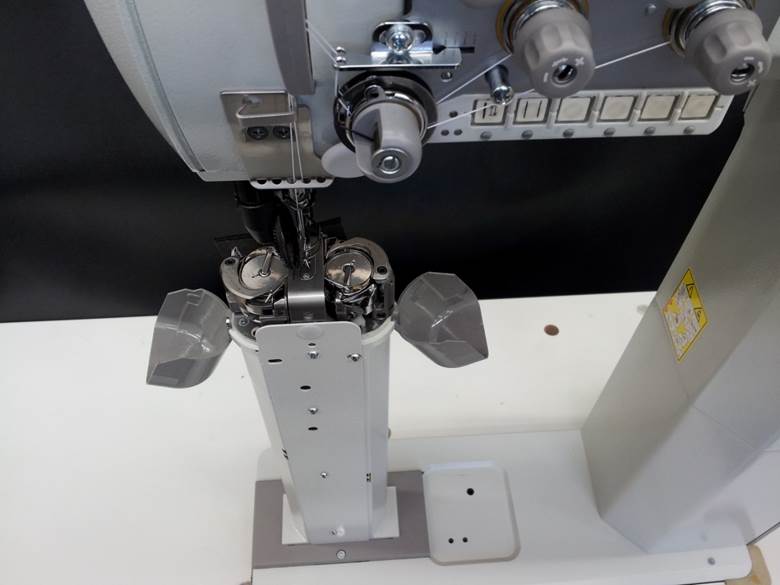

- Trimming device with vertical knife

- Different trimming margins

- Highest precision on stitch locking even during sewing speed changes

- Automatic bobbin winder with start up function

- Low noise and vibration

- The powerful and effective feeding system with wheel feed, needle feed and driven roller presser guarantees excelent material feed when processing different material thicknesses

- Feeding wheel with cross grooving for minimized marks on the fabrics

- Equipped by large hook (26 mm bobbin)

- Simple needle guard adjustment by screw

- Device for controlling the difference between the upper and bottom feed from +10 % to –10 % (optional)

- Fast dismantling of hook

- Lubricating system with central oil tank and oil pump

- Integrated built-in motor to save energy, easy maintenance

- Switch button for setting a reduced stitch, e.g. at material borders (optional)

- Integrated keypad with ergonomically arranged sensor key

- Fully integrated solenoids (887-363122-M)

- Integrated LED sewing light (optional)

- Easy maintenance and access, only a few tools needed

887-363522-M

Additional advantages

- Pneumatically switcheable edge trimming knife

- Air blower of thread tails from stitching area (optional)

- Integrated 2nd stitch length and switchable thread tension

- Electro-pneumatic seam back-tacking and presser foot lift