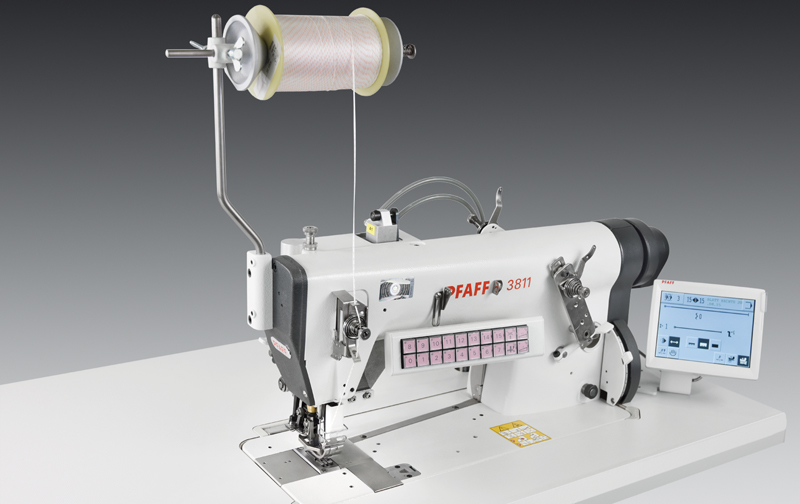

887-260020

Twin needle lockstitch flat bed machines for stitching operations in the shoe production with integrated Direct Drive

887-M

ECO

Twin needle lockstitch post bed machines for stitching operations in the shoe production with DA Direct Drive

Your advantages

- Highest precision on stitch locking even during sewing speed changes

- Secured sewing start after cutting can be influenced by movable needle plate inserts

- Automatic bobbin winder with start up function

- Manual switchable second thread tension for optimised sewing results

- Low noise and vibration

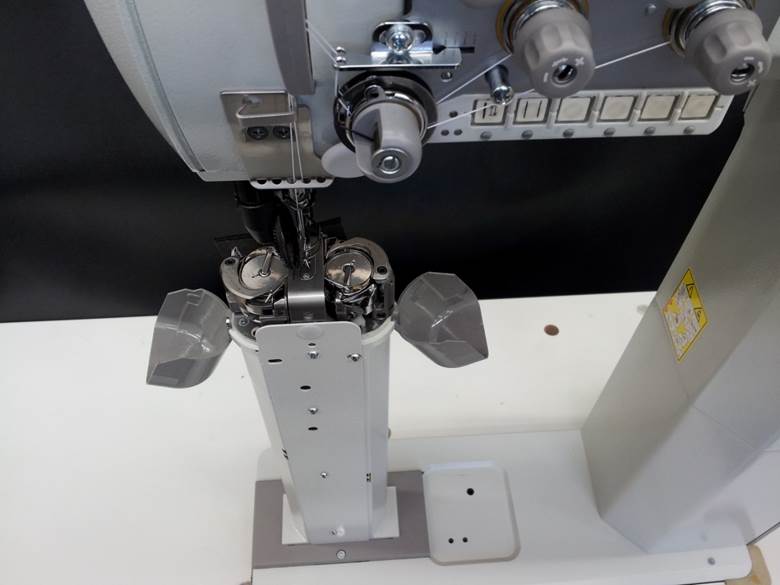

- The powerful and effective feeding system with wheel feed, needle feed and driven roller presser guarantees excelent material feed when processing different material thicknesses

- Feeding wheel with cross grooving for minimized marks on the fabrics

- Feeding wheel covered by rubber, for mark-free sewing (optional for single needle machines)

- Equipped by large hook (26 mm bobbin)

- Simple needle guard adjustment by screw

- Device for controlling the difference between the upper and bottom feed from +10 % to –10 % (optional)

- Fast dismantling of hook

- Needle change without tools (single needle machines)

- Lubricating system with central oil tank and oil pump

- Roller presser setting by operator without tools (optional)

- Integrated built-in motor to save energy, easy maintenance

- Integrated LED sewing light (optional)

- Easy maintenance and access, only a few tools needed