888-356020

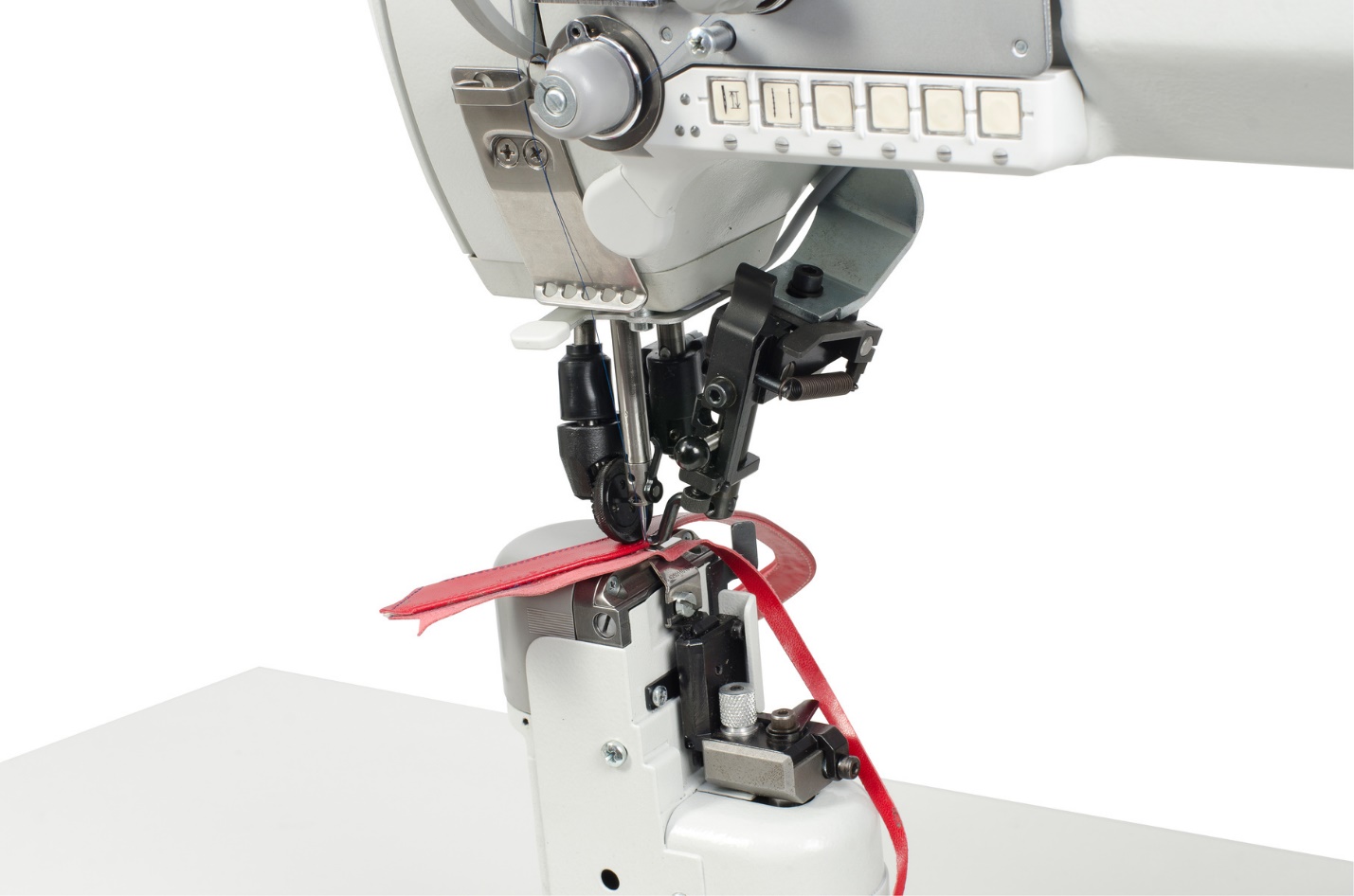

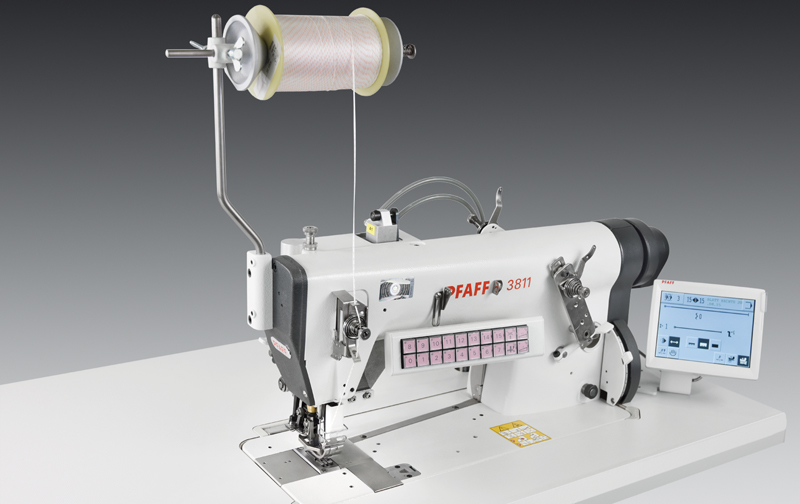

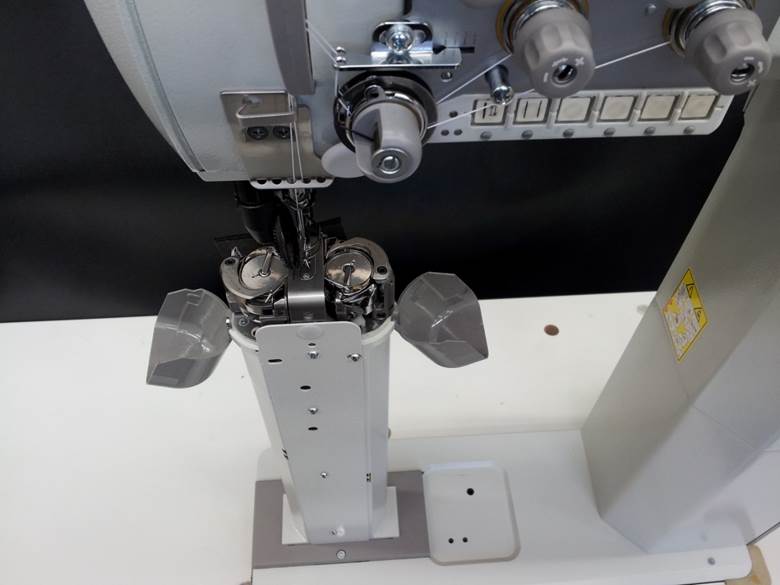

Single needle lockstitch post-bed machine with integrated Direct Drive, wheel feed, needle feed and top driven roller. With left post and lining trimmer from the bottom.

888-M

ECO

Post bed machines with integrated direct drive for inserting lining and undertrimming

Your advantages

- Highest precision on stitch locking even during sewing speed changes

- Secured sewing start after cutting can be influenced by movable needle plate inserts

- Automatic bobbin winder with start up function

- Manual switchable second thread tension for optimised sewing results (ECO)

- Low noise and vibration

- The powerful and effective feeding system with wheel feed, needle feed and driven roller presser guarantees excelent material feed when processing different material thicknesses

- Easy throat plate change without tools (Option for single needle machines)

- An easy replacement of wheel feeder without tools (singleneedle machines)

- Standard hook (22 mm bobbin) or large hook (26 mm bobbin), as per subclass

- Simple needle guard adjustment by screw

- Device for controlling the difference between the upper and bottom feed from +10 % to –10 % (optional)

- Fast dismantling of hook

- Needle change without tools (single needle machines)

- Lubricating system with central oil tank and oil pump

- Roller presser setting by operator without tools (optional)

- Integrated built-in motor to save energy, easy maintenance

- Switch button for setting a reduced stitch, e.g. at material borders and integrated keypad with ergonomically arranged sensor key (advanced functions optional for CLASSIC)

- Fully integrated solenoids (CLASSIC), no compressed air required

- Integrated LED sewing light (optional)

- Easy maintenance and access, only a few tools needed